For any element and part no matter how important or which size, the students had to provide Technical Drawings of the complete showcase including the 360° webcam system to make visibility possible before starting manufacturing. That means that every single piece and then every module had to be planned and prepared in the work groups, then combined in work lines and finally transformed into CNC-code for the wood milling process or STEP-files used in 3D-printing. Making sure that every part and element then would in the end do its job was a huge challenge for every participant.

| CAMERA SYSTEM Assembly STEP-File |

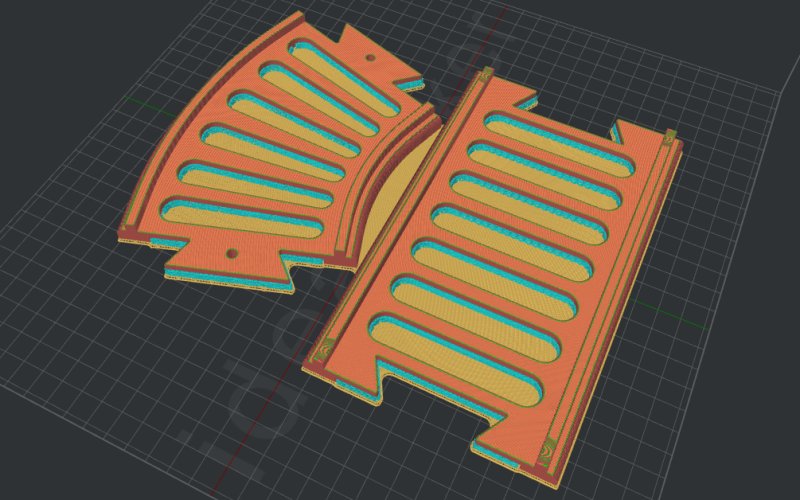

CAMERA SYSTEM 3D-Printing STL-Files |

CAMERA SYSTEM Parts List |

|

|

|

| SHOWCASE Assembly STEP-File |

SHOWCASE Component STEP-Files |

SHOWCASE Parts List |

|

|

|

| RAILWAY TRACKS 3D-Printing STL-Files |

optionally SHOWCASE XL (scaled to fit the tracks) |

|

|